Engineered Materials Portfolio Brochure

Download

Learn more about our new customer portal

Customer Portal

Celanese Corporation is a global technology leader in the production of specialty materials and chemical products which are used in most major industries and consumer applications.

Celanese is a leading global supplier of high-performance engineering polymers designed to drive growth and innovation across all industries. We focus the full power of our development support services, advanced products and deep technical knowledge on the success of our customers, helping redefine the limits of material performance in the most demanding applications. Free yourself to innovate with the many advantages of thermoplastics:

Experience the Advantages of Performance Driven Solutions™

Advancing Material Technologies

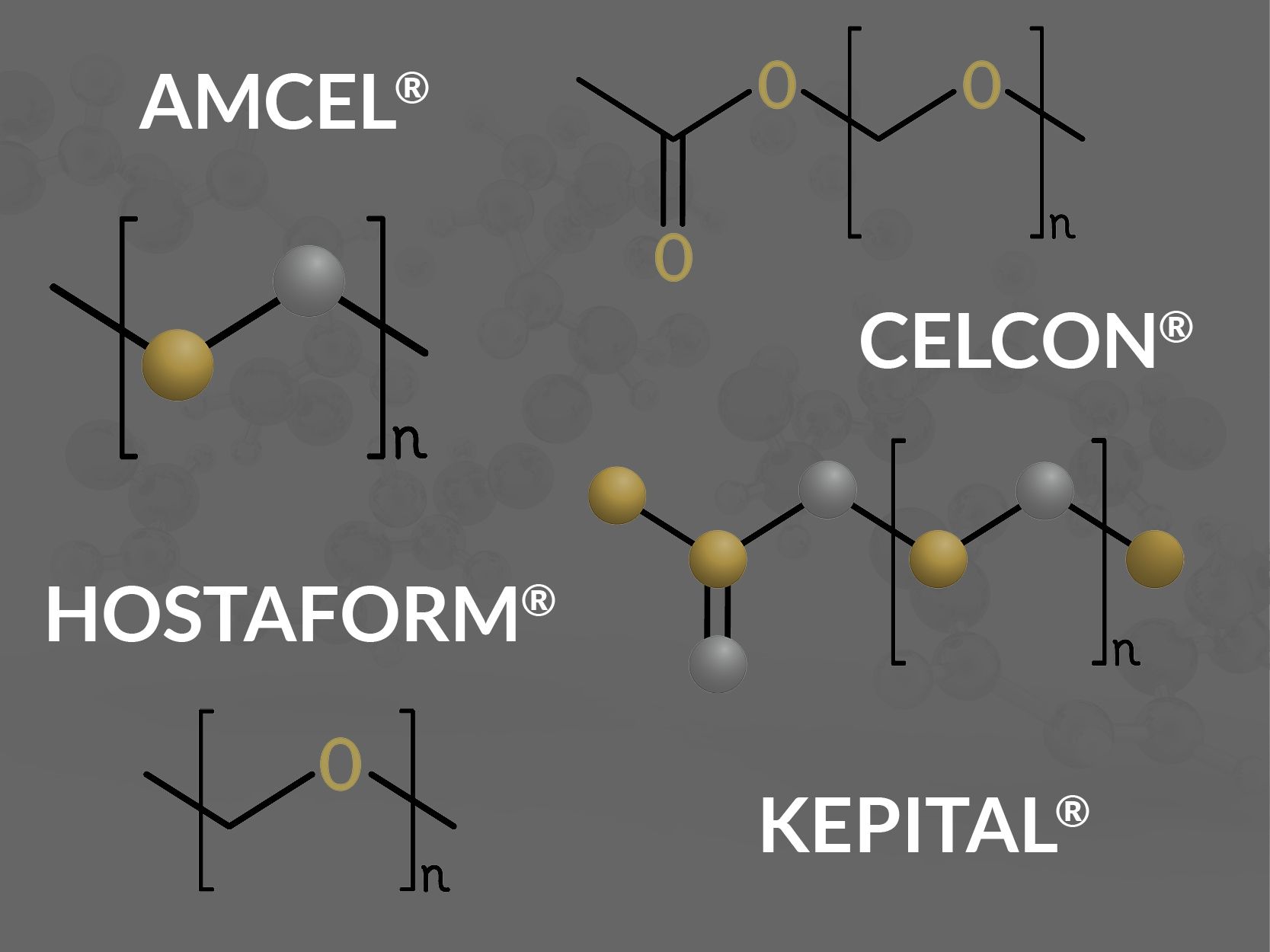

Our products are industry leaders in acetal polymers, liquid crystal polymers, long fiber reinforced thermoplastics, and ultrahigh molecular weight polyethylene and include:

Welcome to the world of Polyoxymethylene (POM), a remarkable engineering polymer renowned for its outstanding properties and versatile applications. Commonly known as acetal, POM offers exceptional mechanical strength, low friction, and excellent dimensional stability, making it a top choice in various industries. From automotive components and consumer electronics to engineering parts and beyond, POM's unique combination of properties enables the creation of high-performance solutions. Join us as we delve into the fascinating characteristics and diverse applications of Polyoxymethylene, an essential material driving innovation across the globe.

Discover the remarkable performance and versatility of Celanese Polyoxymethylene (POM) Product Offerings - engineered to elevate your projects and bring innovation to life!

The future of the automotive industry is driven by developments in autonomous and connected vehicles, and electric vehicles are dramatically changing automotive engineering and associated charging technology. The merger of the E&E industry with the Automotive industry involves a wide range of new requirements for engineering thermoplastics.

Celanese offers OEMs and suppliers a broad portfolio of engineered materials to successfully navigate the powertrain transition with unique material solutions meeting a wide range of needs. Our materials provide flame retardancy, electrical and thermal properties and sustainability and recycled materials. Our extensive experience in the automotive industry enables us to translate our knowledge from E&E to develop innovative solutions for future mobility.

Celanese focuses on innovation that breaths new light into their offerings. They create fresh solutions, find new uses for mature products and improve processes for proven workflows. Accomplishing this through Strategic Translation a focus on bringing differentiated solutions and capabilities to their customers.

Overall growth in biological drugs and in large volume (>2 ml) therapy biopharma products, reduction of injection frequency, increase in patients comfort, cost containment pressure and connectivity being integrated into healthcare are accelerating medical innovation in the wearable devices space.

Celanese portfolio of engineered materials for large volume wearable pumps includes Vectra® MT® LCP for design and production efficiencies in internal chassis, and Hostaform® MT® SlideX® POM for enhanced patient experience when used in internal components.

Celanese MT® service package ensures industry-leading regulatory support to reduce risks during regulatory approval processes and provides for secure and consistent high quality material supply throughout product life-cycle (change notification).

Download our solution showcase to explore how Celanese is creating customer value in the inhalers space.

MetaLX® appearance polymers enable automotive interior visual unity while delivering cost savings and manufacturing efficiencies over painted or chrome-plated metallic appearance parts. Celanese provides outstanding technical support across the value chain from early in development through commercialization to achieve success in in applications like door and console trim, steering wheel bezels and release handles.

Download our solution showcase to learn more about our material differentiation including:

Premium mobile phones are adding new, advanced imaging features – higher resolutions, augmented reality, 3D sensing – which require new multi-lens / array Compact Camera Modules and Voice Coil Motor-driven auto-focus and image stabilization.

For mobile devices, Zenite® LCP SEA grades are specialized solutions that offer production efficiencies in the manufacturing of camera modules (CCMs) and associated components (e.g., VCM carrier, spacer, base).

Our solution showcase will provide more context and case studies on our solution differentiation in the following applications:

Shifting from metal to plastic creates more opportunities for automakers than just reducing weight. Recycled polyamide compounds from Celanese enable manufacturers achieve their recyclability goals while meeting performance requirements for applications previously using prime PA.

Applications for the automotive industry need to fulfill challenging requirement to meet mandatory specifications. Automotive engine compartment parts using recycled grades could provide functional benefits like heat and chemical sealing and even aesthetic benefits for engine beauty covers.

Ecomid® PA recycled grades are part of a broad portfolio of polymers for use under high temperature and chemical conditions.

Download our solution showcase leaflets to learn more about our material differentiation.

Future mobility concepts demand to implement an increased number of e-motors to improve comfort and efficiency levels of modern cars. Materials used in under-the-hood applications need to withstand challenging conditions – no compromises allowed in terms of safety, quality and service life. Celanese provides high performance polymers to provide higher efficiency even in smaller motors that allow manufacturers to reduce cost and weight.

Fortron® PPS and Vectra® and Zenite® LCP grades are part of a broad portfolio of polymers for use under very high temperature and chemical conditions.

Download our solution showcase to learn more about our material differentiation including:

Inhalers are complex, functional, highly differentiated devices. Celanese long track record in medical inhalers helps OEMs, molders and design houses develop and launch next generation devices.

Celanese offers multiple solutions to address critical needs across all medical inhaler types and their components, improving patient experience & device usability and helping deliver effective & efficient treatment:

Celanese MT® service package ensures industry-leading regulatory support to reduce risks during regulatory approval processes and provides for secure and consistent high quality material supply throughout product life-cycle.

Download our solution showcase to explore how Celanese is creating customer value in the inhalers space.

Celanese delivers customer value through material innovations for appearance and haptics in large and small appliances. By leveraging our broad portfolio of engineered material solutions, beautiful surface finishes are achieved while also producing excellent mechanical performance.

Celanese’s portfolio of engineered material solutions address needs in large and small appliance appearance:

Celanese has a long track record as a material supplier for the personal care industry with a broad portfolio of engineered thermoplastics, thermoplastic elastomers and customer enabling capabilities to solve customer challenges in the Soft Touch Razors and Shavers marketplace.

Celanese hard & soft material solutions address needs in personal care segment include shavers and razor sub-segment:

At Celanese, we strive to create opportunities in which we can offer products and applications that maximize the value of our resources. Through our advancements in circular economy, we are able to renew and restore materials at all phases of a products life cycle. This in turn creates value for our customers while reducing waste and environmental impact.

Our key focus areas:

Bio-based – products that contain commercial or industrial goods that are made of all or partial biological products, forestry materials, or renewable domestic agricultural materials, including plant, animal, or marine materials.

Recycled Content – products which are post-industrial or post-consumer that contain recycled content while still maintaining the quality, consistency and performance of the material.

End-of-Life – products that can be restored and reused from the waste stage of life and turned into new materials and products.

These areas of focus prevent the disposal of valuable materials and reduces the amount of new raw materials used in our environment, decreasing the amount of energy usage and pollution. Discover how Celanese can bring value while meeting these important environmental standards.